Design Technique

Design Technique1、Mold Layout: Reasonable parting, prioritized application of oil cylinder drive for slider, assembly and quick replacement of vulnerable parts for mold pins, comprehensive consideration of production efficiency, stability, and service life.

2、Gating system: Select the optimal gating position, fully consider the suitable die-casting production process and the simplicity and efficiency of product processing in the later stage.

3、Vent system: Carefully designed air venting, reasonable selection of vent blocks and vacuum valves, to solve the problem of air hole defects caused by parts that are prone to curling up.

4、Temperature control system: professionally designed cooling water and heating oil circuits based on product structure, to solve problems such as easy shrinkage caused by thick wall, difficult forming and easy deformation.

Industry Experience

Industry Experience1、A senior engineering leader with 20 years of experience in mold design and manufacturing, a senior technical team composed of 14 people, with an average of 8 years of industry experience.

2、More than 50 parts development experiences every year, providing the best solution from product collaborative development, mold design to die-casting process molding.

3、The optimal mold structure design for similar products can be called up at any time from over 2000 sets of die casting mold experience data.

4、The produced die-casting parts cover almost all application fields: traditional/new energy vehicles, communication/5G, electrical/lighting, motors/pump valves, mechanical manufacturing, aerospace, military/instruments, etc.

Patents Obtained

Patents Obtained1、《An exhaust valve structure for molds》.

2、《A locking inclined core pulling for molds》.

3、《A clamping force relief structure for molds》.

4、《A die casting cavity layout for pump body forming》.

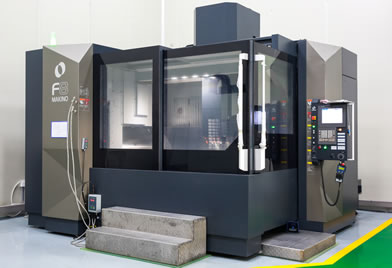

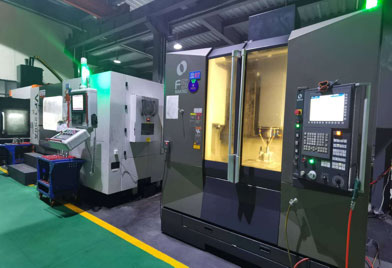

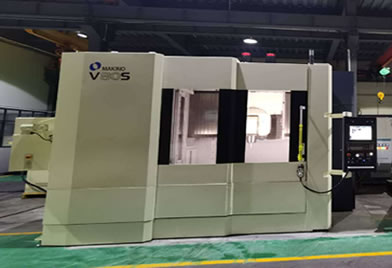

Processing Equipment

Processing Equipment1、A complete range of high-end processing equipment, with a processing accuracy of up to 0.01mm.

2、2 high-speed milling machines, 10 CNC machines, 3 engraving machines, 6 wire cutting machines, and 1 die spotting machine。

3、High complexity processing capability.

4、Standardized workshop operation criterion.

CNC 13 sets: Kohler, Gaofeng, Haitian, Qiruida

High speed CNC

High speed CNC High speed CNC

High speed CNC High speed CNC

High speed CNC High speed CNC

High speed CNC High speed CNC

High speed CNC Cutting Tools

Cutting Tools