Product Review

Product ReviewProduct structure and wall thickness analysis

Dimensional accuracy review

DFM reporting and product optimization

Mold Design

Mold DesignOptimization of die casting process by mold flow analysis

Early detection of design deficiencies through 3D simulation

Mold 3D modeling and review

Mold machining process review

Mold Material

Mold MaterialLarge brand materials

Centralized procurement (excluding customer specified)

Strict material warehousing inspection

Mold Manufacture

Mold ManufactureHigh precision CNC

CMM test to ensure the dimensions of machined parts within the tolerance range

Assemble under the operation instructions to reduce accumulated errors

Quality Inspection

Quality InspectionProcess inspection/testing

Inspection before mold tryout and sample test

Mold delivery inspection

Tryout & Transfer

Tryout & TransferThe materials for mold tryout in accord with the part material, and the trial machine in accord with the customer's die-casting tonnage

Detailed record of mold tryout parameters for customer reference during production

Complete mold information

High Pass Rate

High Pass Rate Long Die Life

Long Die Life Fast Diecasting Rhythm

Fast Diecasting Rhythm Good Stability

Good Stability Low Failure Rate

Low Failure Rate Easy Maintenance

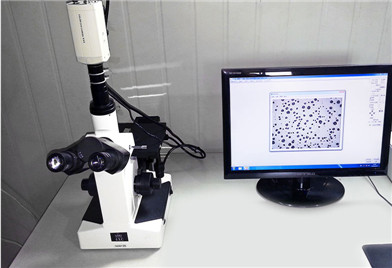

Easy Maintenance Roundness Meter

Roundness Meter  Hardness Meter

Hardness Meter Spectrometer

Spectrometer  Zeiss CMM

Zeiss CMM  Roughness Meter

Roughness Meter Cutting Tools

Cutting Tools